Description

Introduction:

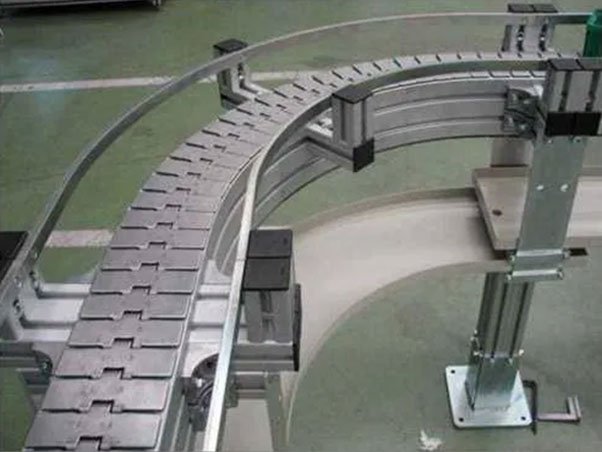

A Slat Chain Conveyor is a heavy-duty material handling system designed to transport products on flat, rigid slats mounted over continuous chains. It is especially suitable for applications where products are heavy, hot, oily, sharp-edged, or require stable support during conveying. Slat chain conveyors are widely used in automotive, engineering, assembly, and manufacturing industries where reliability and durability are critical.

At Tech Trek Engineering, we design and manufacture slat chain conveyors that are robust, precise, and fully customized according to application requirements. Our conveyors are engineered to deliver smooth product flow, long service life, and consistent performance in demanding industrial environments.

What is a Slat Chain Conveyor?

A slat chain conveyor is a conveyor system in which slats made from metal or engineered materials are mounted on one or more endless chains. These slats form a continuous moving surface that carries products along the conveyor path.

Unlike belt conveyors, slat chain conveyors can handle heavy loads, high temperatures, and harsh conditions without damage or slippage.

Working Principle:

The working principle of a slat chain conveyor is based on synchronized chain movement:

- A geared motor drives the head sprocket.

- The sprocket pulls the conveyor chain forward.

- Slats attached to the chain move along the conveyor track.

- Products rest on the slats and move smoothly with the conveyor.

- At the discharge point, products are transferred to the next process.

- The chain and slats return through the lower track to complete the cycle.

This mechanism ensures stable and controlled movement of products.

Key Features of Slat Chain Conveyor:

- Heavy-duty and robust construction

- Stable conveying surface

- Suitable for hot, oily, or abrasive materials

- High load-carrying capacity

- Smooth and controlled movement

- Long service life

- Low maintenance requirement

- Customizable design

Types of Slat Chain Conveyors:

Based on application and design requirements, slat chain conveyors can be designed as:

- Single-strand slat chain conveyor

- Double-strand slat chain conveyor

- Heavy-duty slat chain conveyor

- Slat chain conveyor with fixtures

- Inclined slat chain conveyor

Each type is customized to match product characteristics and production requirements.

Slat and Chain Options:

We offer a variety of slat and chain configurations:

- Slat Material: Mild Steel, Stainless Steel, Aluminium

- Slat Type: Flat slats, perforated slats, customized slats

- Chain Type: Single-strand or double-strand chains

- Chain Material: Alloy steel or stainless steel

Slat thickness and chain pitch are selected based on load and application.

Applications of Slat Chain Conveyor:

Slat chain conveyors are widely used in:

- Automotive assembly lines

- Heavy engineering industries

- Machine shops and fabrication units

- Foundries and metal processing

- Painting and coating lines

- Assembly and inspection stations

They are ideal for handling components, engine blocks, metal parts, and fixtures.

Advantages of Slat Chain Conveyor:

- Handles heavy and hot materials easily

- Provides stable support for products

- Performs reliably in harsh environments

- Long operational life

- Low maintenance with proper design

- Suitable for continuous operation

- High durability

Customization Options:

We provide extensive customization options, including:

- Conveyor length and layout

- Slat width, thickness, and material

- Chain type and strand configuration

- Variable speed control

- Fixtures and locating pins

- Heavy-duty or corrosion-resistant construction

Slat Chain Conveyor – FAQs:

Q1. What materials can be handled using a slat chain conveyor?

Slat chain conveyors can handle heavy, hot, oily, and abrasive materials.

Q2. What is the difference between a slat chain conveyor and a belt conveyor?

Slat chain conveyors are used for heavy-duty applications, while belt conveyors are suitable for lighter materials.

Q3. Can slat chain conveyors be used in assembly lines?

Yes, they are commonly used in automotive and heavy assembly lines.

Q4. Is speed control available in slat chain conveyors?

Yes, variable speed control can be provided using VFD or PLC systems.

Q5. What factors affect the price of a slat chain conveyor?

Price depends on conveyor length, slat material, chain type, load capacity, and customization.

Q6. Are slat chain conveyors suitable for inclined conveying?

Yes, inclined slat chain conveyors can be designed based on application requirements.

Q7. Do you provide installation and commissioning support?

Yes, we provide complete technical support during installation and commissioning.